01. Occupational Asbestos Exposure

What Is Occupational Asbestos Exposure?

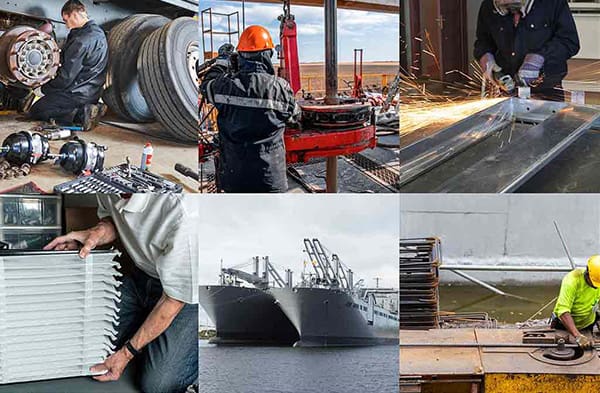

Occupational asbestos exposure occurs when workers are exposed to asbestos on the jobsite or through their work-related tasks. Construction workers, auto mechanics and shipyard workers are just a few high-risk occupations. Asbestos jobs were common during much of the 20th century.

Between 1940 and 1979, approximately 27 million Americans experienced asbestos exposure at work. These workers are at risk of developing asbestos-related diseases, such as mesothelioma. According to the Centers for Disease Control and Prevention (CDC), approximately 54,905 people died from mesothelioma between 1999 and 2020.

Asbestos-related diseases typically have long latency periods spanning decades. This means individuals exposed while working in the past may now face adverse health effects.

Workers at some jobsites may continue to face exposure risks. Those currently exposed to asbestos on the job may not be diagnosed with a disease for several more decades.

No amount of asbestos exposure is safe and many workers may encounter asbestos on the job. However, certain occupations are historically at high risk of asbestos exposure.

02. High-Risk Occupations

High-Risk Asbestos Occupations

Asbestos occupations are considered high risk if there is a high likelihood of repeated or concentrated exposure. These jobs often required people to handle asbestos products frequently. People who worked these jobs have higher rates of asbestos disease. High-risk jobs include those in the construction and oil refining industries. Firefighters may also experience high levels of exposure.

Aircraft Mechanics

Aircraft mechanics may have experienced asbestos exposure while servicing various aircraft systems. Asbestos was most commonly found in brake and landing gear systems. Some aircraft brake types contained up to 23% asbestos by weight. As a result, mechanics working around these systems may have been exposed to asbestos.

Auto Mechanics

Auto mechanics may have come into contact with asbestos while servicing cars and replacing parts in automobiles. Asbestos was frequently used in high-friction materials, such as brakes, clutches and heat shields. Replacing these parts requires removing the old components, which could release asbestos dust. As a result, auto mechanics may have inhaled asbestos fibers. These professionals may still come into contact with asbestos in older vehicles and parts.

Boiler Workers

Boiler workers may have come into contact with asbestos while manufacturing, installing, servicing and repairing boilers. Asbestos was frequently used in many components of boilers and other HVAC equipment. The mineral was used to withstand the high temperatures of these systems.

Construction Workers

The CDC notes employees in the construction industry are among those with the highest rates of asbestos exposure. An estimated 1.3 million construction workers come into contact with asbestos on the job each year. Construction workers often work inside older buildings and homes. These structures used the mineral for fire resistance and durability. Floor and ceiling tiles, joint compound, siding and plaster are all common asbestos-containing construction products.

Firefighters

Firefighters are among the most likely to come in contact with asbestos fibers. Asbestos exposure among firefighters occurs when fighting fires within homes and buildings built before 1980. These structures often contain many different asbestos products. Common asbestos products include insulation, tiling, vinyl flooring and roofing materials. Studies have shown firefighters are twice as likely to develop mesothelioma compared to the general public. The increased risk is largely due to repeated exposure while responding to emergencies.

HVAC Workers

HVAC workers, boilermakers and pipefitters all sometimes work in tight spaces where asbestos was used. These workers may risk exposure from working inside public buildings and residential homes. Workers in this industry may be exposed to high concentrations of airborne asbestos fibers while performing maintenance work or installations. HVAC workers may also risk exposure while repairing boilers installed decades ago that used asbestos materials.

Industrial Workers

Industrial workers are often employed in factories and power plants, working in areas where high heat and chemical exposure are common. Workers may come into contact with asbestos while handling refractory products, gaskets and valves. Even protective clothing worn to resist high temperatures often contained asbestos.

Insulators

Insulators were exposed to asbestos in many types of insulation products. These materials contained asbestos from the mid-1860s through about 1978. As a result, thousands of insulators have been exposed to asbestos. Today, insulators may still come into contact with asbestos insulation in older homes, schools, buildings, ships and machinery.

Machine Operators

Machine operators work in factories and plants and often operate heavy equipment, such as bulldozers and cranes. Workers in these jobs frequently came in contact with high-friction asbestos products, such as brake linings. As machine operators perform their daily duties, they may ingest or inhale asbestos fibers.

Machinists

Machinists use tools and machinery to make industrial parts. For many years, asbestos was added to machinery to improve durability. Machinists may have come in contact with asbestos at a variety of jobsites, such as on ships. They often worked in poorly ventilated boiler and engine rooms. Working conditions caused many machinists to experience asbestos exposure. Machinists may still risk exposure from old asbestos products.

Mine Workers

Asbestos mine workers may have inhaled the mineral during the mining and packaging process. Asbestos is a naturally occurring mineral that was mined for decades in the 20th century. Workers in these mines experienced daily asbestos exposure. Studies show asbestos mine workers have extremely elevated rates of lung cancer and mesothelioma. Asbestos products may also have been used in other types of mines, such as coal mines.

Oil Refinery Workers

Oil or petroleum refinery workers help process the fuels and oils Americans use every day. These workers often encounter asbestos inside of old electrical products, cement, protective clothing and thermal insulation. Research has shown workers in this industry typically face prolonged asbestos exposure. As a result, workers at oil refineries have one of the highest mesothelioma mortality rates.

Shipyard Workers

Shipyard workers often worked with asbestos-containing materials while building and repairing ships. Because of the risk fire poses to ships at sea, asbestos materials could be found almost anywhere on the vessels. For example, ships often had asbestos insulation, pipe coverings and valves. Due to the mineral’s wide use, workers at shipyards are among the most at risk of developing mesothelioma and other asbestos diseases.

Teachers

Teachers may have been exposed to asbestos in schools. Asbestos was used frequently in schools built before 1980. Some records indicate nearly a third of the nation’s schools may have been built with asbestos products. As school buildings age, older asbestos materials have begun to decay and release fibers. As a result, teachers may experience asbestos exposure.

Textile Mill Workers

Textile mill workers were often responsible for making, cutting and handling fabrics. Workers may have been exposed to asbestos while making asbestos fabrics. Studies show increased incidences of mesothelioma, lung cancer and asbestosis in textile mill workers compared to the general population.

03. Medium-Risk Occupations

Medium-Risk Asbestos Occupations

Medium or moderate at-risk asbestos occupations include workers who have infrequent asbestos exposure or face a moderate concentration of asbestos fibers. Jobs like Merchant Mariner deployment, metal work and railroad work carry a moderate risk of asbestos exposure. Cement, chemical and paper plant workers also face moderate exposure risks at their jobs.

Although people within these occupations may not work with asbestos every day, it’s important to note there is no safe level of asbestos exposure. Medium-risk individuals may still develop asbestos-related diseases later in life.

Carpenters

Carpenters may have come into contact with asbestos in construction materials. Many building products contained the mineral, including insulation, tiles and underlayment. Carpenters may have been exposed to these products during construction and renovation projects. Although the mineral is rarely used today, carpenters still risk exposure from asbestos products when working in older homes and buildings.

Cement Plant Workers

Cement plant workers are responsible for mixing cement and manufacturing cement products. Asbestos fibers were added to many cement products for durability and temperature resistance. Cement workers may have been exposed to asbestos while mixing the cement or forming it into sheets and blocks.

Chemical Plant Workers

Chemical plant workers may have come into contact with asbestos components in equipment and machinery. Asbestos was used in chemical plants for chemical durability and heat resistance. Common sources of exposure in chemical plants include protective equipment, cement, pipe insulation and boilers.

Electricians

Electricians are responsible for installing, maintaining and repairing electrical systems. This work brought electricians in contact with various asbestos products. The mineral was used frequently before 1980 in electrical panels, wiring insulation and other common construction products. Asbestos was used in electrical systems for insulation and temperature resistance.

First Responders

First responders may come into contact with asbestos during rescue missions or disaster response efforts. Asbestos was frequently used in construction materials produced before 1980. Natural disasters and other catastrophes may destroy buildings and cause the release of these fibers. As a result, first responders may be at risk of asbestos exposure.

Merchant Mariners

Merchant Mariners are associated with the U.S. Navy and spend much of their time aboard ships. Some may have been exposed to asbestos while performing repairs and other maintenance away from port. The mineral could be found throughout the ships, especially in boiler and engine rooms due to the heat generated in those areas. Due to the high rates of asbestos exposure, one study of 3,000 Merchant Mariners discovered lung abnormalities in about 40% of those workers.

Metal Workers

Asbestos was often sprayed on metal beams for fire resistance and attached to metal materials bent, drilled and shaped by metal workers. Steel mills, aluminum plants and other industrial settings commonly used asbestos in the manufacturing process. Metal workers could also face exposure from asbestos in protective clothing, including inside gloves and blankets. Welders and lathers may have been exposed to asbestos in welding products and plaster.

Paper Mill Workers

Asbestos was used in paper mills during the pulp-drying process. Paper mills used asbestos felt to assist in the high-temperature drying process. Workers who oversaw these processes or serviced the drying equipment may have come into contact with asbestos fibers.

Plumbers

Plumbers, pipefitters and steamfitters may experience asbestos exposure from pipe systems and other materials. Pipes, valves and other plumbing products commonly contained asbestos. The mineral was used to make pipe systems resistant to heat and corrosion. Plumbers maintain and repair pipes in homes, buildings and industrial jobsites. Plumbers continue to risk exposure when working in buildings constructed before 1980.

Railroad Workers

Asbestos was widely used throughout much of the 20th century in the railroad industry. It can be found in everything from flooring inside of train cars to brake pads, rail ties and steam engines. Railroad workers may also face exposure from naturally occurring asbestos while digging new rail lines.

04. Low-Risk Occupations

Low-Risk Asbestos Occupations

Low-risk asbestos jobs are defined by one or more of the following:

- Bystander asbestos exposure

- Exposure to low concentration of asbestos fibers

- Minimal direct asbestos exposure

Low-risk asbestos occupations include engineers, farmers and hairdressers. Workers in low-risk occupations may be less likely to develop asbestos-related diseases than other occupations. However, no amount of asbestos exposure is safe. These workers may still experience asbestos-related diagnoses following occupational asbestos exposure.

Appliance Installers

Appliance installers and technicians may have been exposed to asbestos in home appliances. Most manufacturers no longer use asbestos in their products. However, appliance installers may still come into contact with older materials that contain asbestos.

Chimney Sweeps

Chimney sweeps are often exposed to lung irritants, including asbestos. The mineral was often used in building insulation and pipes, which may be exposed in chimneys. As a result, chimney sweeps may come into contact with asbestos while cleaning and servicing chimneys. These individuals have also reported a higher incidence of pleural diseases, including mesothelioma.

Engineers

Engineers are employed in a variety of industries. They often don’t work directly with asbestos or asbestos-containing products. However, engineers may supervise and work closely with employees who do interact with the mineral. Oftentimes, an engineer’s exposure is connected to working in the same area as employees who are handling asbestos materials.

Farmers

The farming industry has shown high rates of asbestos exposure. Asbestos affects dairy farmers, poultry farmers, agricultural equipment operators and many other farming trades. Exposure has occurred during operation and repairs of farming equipment with asbestos-containing components. Farmers also risk exposure from the deterioration and renovation of old farm buildings. Some farmers may work near naturally occurring asbestos, which could cause exposure when land is disturbed.

Hairdressers

Hairdressers are at risk of coming into contact with asbestos fibers through prolonged and frequent use of older hair dryers. These hair dryers often contained the mineral as an insulator. Asbestos is no longer used in hair dryers today. But studies have shown older hair dryers produced before the late 1970s did release fibers into the surrounding air.

05. Asbestos Regulations

Federal Asbestos Regulations to Protect Workers

To protect the workforce, there are federal regulations in place to manage asbestos exposure on the job.

The Occupational Safety and Health Administration (OSHA) first regulated workplace asbestos exposure in the 1970s. Today, OSHA has strict guidelines on the acceptable amount of airborne asbestos fibers at a jobsite. OSHA guidelines also require labeling of all asbestos on jobsites and that workers receive proper personal protective equipment.

The occupations listed above are only a few of the many types of workers at risk of developing asbestos-related diseases. OSHA reports stress there is no safe level of occupational asbestos exposure. Those who believe they’ve experienced asbestos exposure at work should seek medical attention and file a complaint with OSHA.

06. Common Questions

Common Questions About Asbestos in the Workplace

-

What should I do if I’ve been exposed to asbestos at work?

- If exposed at work, you may want to keep a record of the event. Workers can also discuss asbestos exposures with their doctors. A medical expert can monitor for symptoms of mesothelioma, like difficulty breathing. The disease has a long latency period and may or may not develop decades after exposure.

-

What occupations are at high risk for mesothelioma?

- Occupations with frequent or concentrated asbestos exposure are considered high risk. Examples of high-risk jobs include auto mechanics and construction, oil refinery and shipyard workers. Any exposure may lead to a mesothelioma diagnosis, but these workers are diagnosed at a higher rate.

-

Is it safe to work around asbestos?

- Any level of exposure is unsafe, although in some situations asbestos fibers may not pose a risk of becoming airborne. Concerned workers can talk to their building manager or employer. Abatement professionals are available to determine if jobsites need to have asbestos sealed or removed.