01. Shipyard History

History

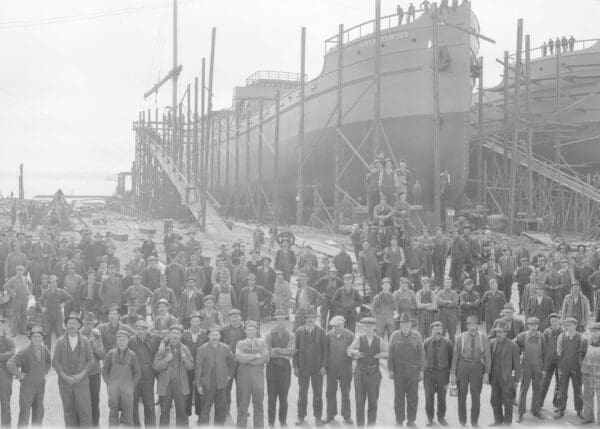

American Shipbuilding Company was incorporated in New Jersey in 1899. It began as a consolidation of the Cleveland Ship Building Co., the Ship Owner’s Dry Dock Co., the Globe Iron Works and five other companies in the Great Lakes region. The company is commonly referred to as AmShip and operated several locations around the United States from 1899 to 1995.

The first of American Shipbuilding Company’s shipyards was in Cleveland, Ohio. It eventually expanded to Lorain, Ohio; Toledo, Ohio; Chicago, Illinois and Tampa, Florida. During World War II (WWII), the company employed more than 2,500 workers.

By 1952, the company was the largest shipbuilder on the Great Lakes.

In 1967, American Shipping Company was purchased by a group of investors. George Steinbrenner, former owner of the New York Yankees, became the chief executive officer. Further expansion occurred in 1972, when the company purchased Tampa Ship & Dry Docks Company and moved headquarters to Tampa in 1979.

However, decreasing orders for lake freighters and labor union disputes led the shipyards in Loraine, Toledo and Chicago to close by 1981.

The Cleveland American Shipbuilding Company location closed in 1983. The company ceased operations in 1995 with the closing of its last location in Tampa.

Today, the Loraine shipyard is home to the HarborWalk, which includes luxury living, pleasure boat docks, dining and event spaces.

American Shipbuilding Company History at a Glance

- Other Names: AmShip, AmericanShip

- Location: Cleveland, Ohio; Lorain, Ohio; Toledo, Ohio; Chicago, Illinois; Tampa, Florida

- Owner(s): George Steinbrenner

- Years of Operation: 1899 – 1995

- Wartime Operations: World War II (WWII)

- Number of Employees: 2,500 during peak

- Noteworthy Ships: USS Seer, USS Staff, USS Mirth, USS Disdain, USS Dour, USS Lorain, USS Lorain County, M/V Paul R. Tregurtha, USS McMorris, USS Wood County, USS Jubilant, USS Sandalwood, USS Redwood

- Types of Ships Built/Serviced: Carriers, minesweepers, passenger ships, tankers, tugs, ferries, oar boats, cruisers, destroyer escorts, landing ships, net layers

Many workers at American Shipbuilding Company were potentially exposed to asbestos. Workers’ loved ones may have also experienced secondhand exposure. As a result, many people developed asbestos-related diseases, such as asbestosis, asbestos lung cancer, pleural mesothelioma and peritoneal mesothelioma. People who developed an asbestos-related disease may be eligible for compensation.

Notable Ships Built and Repaired

American Shipbuilding Company built hundreds of ships in the Great Lakes region. This included commercial and military ships. One such military ship was the USS Redwood.

USS Redwood

In 1940, the American Shipbuilding Company laid down the USS Redwood at its Cleveland, Ohio, shipyard. The USS Redwood was first classified as a yard net tender. Her first assignment was in the British West Indies, installing torpedo nets in Trinidad until March 1943. She served around the West Indies and Caribbean for the remainder of WWII.

In 1944, she was reclassified as a net laying ship. In 1945, the USS Redwood returned to Trinidad to dispose of nets at sea. Soon after, she reported to the Atlantic Reserve Fleet in Green Cove Springs, Florida. She was decommissioned in 1947 and was transferred to the Maritime Administration’s National Defense Reserve Fleet in 1961.

The USS Redwood was built and active during a time of heavy asbestos use on Navy ships. Anyone who worked or served on her was at risk of asbestos exposure and may develop an asbestos-related disease.

02. Shipyard Asbestos Use

Asbestos Use at American Shipbuilding Company

Because asbestos is heat resistant and durable, it was commonly used in ship construction. Raw asbestos and various asbestos products were used throughout ships to help prevent fires. Use of the mineral also helped control heat emitted by machinery, such as boilers and engines.

American Shipbuilding Company was an active worksite from 1899 to 1983. During this time, asbestos was commonly used on ships for construction and in equipment. Workers at American Shipbuilding Company used asbestos as insulation in walls, around pipes, in boilers and elsewhere on ships. As a result, workers came in contact with many products that put them at risk of asbestos-related diseases.

Asbestos Exposure at American Shipbuilding Company

Civilian workers and military service members worked in shipyards and aboard ships. From the 1930s to the 1980s, tons of asbestos were used in shipyards and shipbuilding. As a result, U.S. Navy veterans and civilian workers at American Shipbuilding Company faced a high risk of asbestos exposure and developing malignant mesothelioma cancer.

Those who helped maintain or repair carriers, minesweepers, passenger ships, tankers, tugs, ferries, oar boats, destroyer escorts, landing ships and cruisers also faced these risks. The heavy use of the dangerous mineral, along with poor ventilation on ships, led to frequent asbestos exposure. For example, insulators were exposed through installation and maintenance work.

Although asbestos use ceased at shipyards by the 1980s, workers and visitors may still risk exposure today. Asbestos materials may still be found on ships built before the 1980s and older equipment at shipyards. Working with asbestos insulation, repairing old boilers and other shipyard duties put individuals at risk of exposure.

03. Asbestos Lawsuits

Asbestos Lawsuits and Settlements

People who worked on ships at American Shipbuilding Company are at risk of developing asbestos cancer or other related diseases. After a diagnosis, these shipyard workers have compensation options.

Victims can be compensated by the companies that exposed them to asbestos. Their compensation options depend on the status of that company. Victims can work with a mesothelioma lawyer to secure payment from a lawsuit, settlement, trust fund and/or VA claim (or a combination of these types of claims).

Holding Asbestos Companies Responsible

Some asbestos product manufacturers remain in business today. This means these companies have not filed for bankruptcy and victims can file asbestos lawsuits against the company. Lawsuits may result in compensation through verdicts or settlements.

For example, Spirax Sarco, Inc. supplied steam traps to shipyards such as American Shipbuilding Company. Some of the products Spirax Sarco, Inc. supplied contained asbestos.

Grinell Corp. is another viable company that supplied asbestos materials to shipyards for decades, including during WWII. As a result, people were wrongfully exposed and developed asbestos-related diseases such as mesothelioma.

Some of these victims have filed successful lawsuits against these companies.

04. Filing Asbestos Claims

Asbestos Company Trusts

Wrongful asbestos exposure and the resulting lawsuits have contributed to more than 100 companies filing for bankruptcy in the last 20 years. As part of the bankruptcy process, many asbestos companies created trust funds. Asbestos trust funds provide compensation for current and future victims of asbestos-related conditions.

As part of their job duties, many shipyard employees came into contact with asbestos. Shipyard workers who developed an asbestos-related disease are eligible to file a claim with the product manufacturer’s trust.

Asbestos Company Trust Funds and Eligible Years of Employment

The following companies provided asbestos products to American Shipbuilding Company. After facing many asbestos lawsuits and exposing innocent people to asbestos, these companies filed for bankruptcy and created trusts to pay victims. If an individual worked at American Shipbuilding Company and developed a disease such as mesothelioma, they may be able to file a mesothelioma claim against these companies’ trusts.

| Asbestos Trust Funds & Eligible Years of Employment | ||

|---|---|---|

| Asbestos Company Name | Eligibility Start Date | Eligibility End Date |

| A-Best Products | 1/1/1971 | 12/31/1982 |

| A.P. Green | 1/1/1966 | 1/2/1968 |

| Babcock & Wilcox | 6/1/1917 | 12/31/1982 |

| Combustion Engineering | 1/1/1920 | 12/31/1982 |

| Fibreboard | 1/1/1940 | 12/31/1982 |

| Halliburton | 1/1/1934 | 12/31/1982 |

| NARCO | 12/10/1965 | 10/31/1980 |

| Owens Corning | 1/1/1952 | 12/31/1982 |

| United States Gypsum | 1/1/1966 | 1/2/1968 |