01. Shipyard History

History

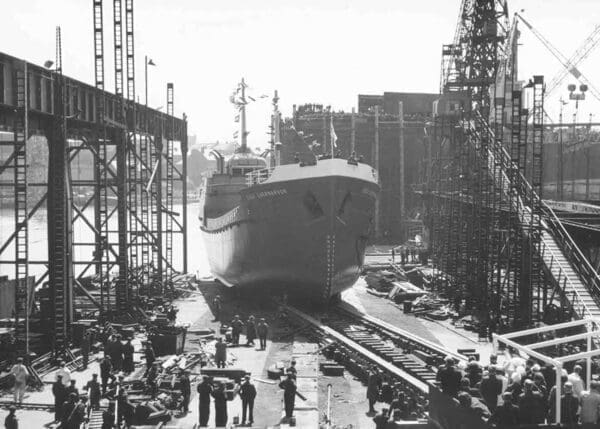

Norfolk Shipbuilding and Drydock Corporation was established in 1915 in Norfolk, Virginia. Throughout its history, the shipyard has been known for ship repair, maintenance and modernization.

Norfolk Shipbuilding and Drydock Corporation played a large role during World War I (WWI) and World War II (WWII). The shipyard’s height of employment was 5,000 people during WWII. At this time, asbestos-containing materials were commonly used in shipbuilding and repair. The use of asbestos materials at Norfolk Shipbuilding and Drydock Corporation put many shipyard workers at risk of exposure.

Today, the shipyard has been renamed BAE Systems Norfolk Ship Repair and employs approximately 2,200 people. The shipyard now has two dry docks, four piers and 16 cranes.

Norfolk Shipbuilding and Drydock Corporation History at a Glance

- Other Names: NORSHIPCO, Norfolk Ship Repair, BAE Systems Norfolk Ship Repair, F.O. Smith Shipbuilding & Drydock

- Location: Norfolk, Virginia

- Owner(s): BAE Systems, United Defense International, U.S. Marine Repair, Smith & McCoy, Southwest Marine

- Years of Operation: 1915 – Present

- Wartime Operations: World War I (WWI), World War II (WWII)

- Number of Employees: 5,000 during WWII

- Size of Shipyard: 109 acres

- Noteworthy Ships: USS Nicholas, USS Flint, USS Briscoe, USS Coronado, USS Detroit, USS Josephus Daniels

- Types of Ships Built/Serviced: Cruisers, jeep aircraft carriers, troop transports, oil tankers, destroyers, fast combat support ships

Many workers at Norfolk Shipbuilding and Drydock Corporation were potentially exposed to asbestos. Workers’ loved ones may have also experienced secondhand exposure. As a result, many people developed asbestos-related diseases, such as asbestosis, asbestos lung cancer, pleural mesothelioma and peritoneal mesothelioma. People who developed an asbestos-related disease may be eligible for compensation.

Notable Ships Built and Repaired

At Norfolk Shipbuilding and Drydock Corporation, workers frequently repaired and maintained U.S. Navy ships. Some notable ships repaired at the shipyard were the USS Briscoe and USS Detroit.

USS Briscoe (DD 977)

The USS Briscoe was a destroyer built at Ingalls Shipyard in 1975. The USS Briscoe began her service in 1978.

The ship’s notable operations include:

- The liberation of Grenada in Operation Urgent Fury in the early 1980s

- The rescue of more than 500 passengers in 1994 from an Egyptian passenger ferry

- The burial at sea of John F. Kennedy Jr., Carolyn Bessette Kennedy and Lauren Bessette in 1999

The ship also participated in defense efforts after the September 11, 2001 attack on the U.S. and in Operation Iraqi Freedom in 2003. The USS Briscoe was homeported at Norfolk Shipbuilding and Drydock Corporation where she would return often for routine repairs. This is also where she was decommissioned in 2003.

Before the 1980s, asbestos was used in shipbuilding and repair. Navy personnel working or serving on the USS Briscoe may be at risk of developing asbestos-related diseases.

USS Detroit (AOE 4)

The fast combat support ship, USS Detroit, was built in 1966 at Puget Sound Naval Shipyard. Originally homeported at Naval Station Newport, the ship was switched over to Norfolk Shipbuilding and Drydock Corporation from 1974 to 1989. In 1985, during one of the USS Detroit’s returns to Norfolk, the ship underwent a three-month repair.

During the USS Detroit’s construction and repair, crew members and workers may have come in contact with asbestos-containing products. These employees may risk developing mesothelioma or another illness.

The ship’s notable operations include:

- Supporting U.S. and allied units of the Multinational Peacekeeping Force in Beirut, Lebanon, in 1983

- Law enforcement support in the Caribbean Sea in 1989

- Operation Desert Storm in 1991

The USS Detroit was decommissioned in 2005.

02. Shipyard Asbestos Use

Asbestos Use at Norfolk Shipbuilding and Drydock Corporation

Asbestos is a durable mineral that is highly resistant to heat. Due to these properties, shipbuilders often used asbestos during the construction process. Products containing asbestos helped control the release of heat and were fire resistant. Such products were desirable on ships.

Norfolk Shipbuilding and Drydock Corporation actively operated from 1915 to the present. Asbestos was commonly used during this time. Asbestos was used throughout Norfolk Shipbuilding and Drydock Corporation. The dangerous mineral was often present in boilers, incinerators, insulating materials and other elements of ships. This put those in various shipyard occupations at risk of developing asbestos-related diseases.

Asbestos Exposure at Norfolk Shipbuilding and Drydock Corporation

It was common for members of the U.S. military and civilians to provide labor in shipyards and on ships. Asbestos was used in most shipyards and aboard most Navy vessels from the 1930s to the 1980s. This likely exposure puts Navy veterans at an increased risk of malignant mesothelioma cancer.

People who constructed or maintained cruisers, jeep aircraft carriers, troop transports, oil tankers, destroyers, fast combat support ships and other ships during this time were likely exposed to asbestos. These people often worked in space-constrained and poorly ventilated areas, which possibly allowed more asbestos fibers to remain in the areas. For example, enginemen and machinists faced asbestos exposure.

Asbestos is no longer used in most manufactured products. However, its historical presence in ships and navy vessels can put people at risk of exposure. People who repair or decommission ships built from the 1930s to the 1980s currently face asbestos exposure. Many shipyard responsibilities, such as installing insulation and pipes, led to frequent exposure.

03. Asbestos Lawsuits

Asbestos Lawsuits and Settlements

Employees and visitors of Norfolk Shipbuilding and Drydock Corporation are at risk of developing asbestos diseases such as mesothelioma and asbestos cancer. If diagnosed, such individuals have several legal options for compensation.

Victims may obtain financial compensation from the companies responsible for their asbestos exposure. Their options will depend on the companies’ current statuses. The best route for any victim is to work with a mesothelioma lawyer who can ensure they pursue and obtain payment from a lawsuit, settlement, VA claim and/or trust fund (or a combination of these types of claims).

Holding Asbestos Companies Responsible

Some companies that wrongfully exposed workers to asbestos are still viable. In other words, they have not filed for bankruptcy. This means individuals can file lawsuits against such companies, which may result in a settlement or verdict.

For example, Armstrong International, Inc. is a viable company that was responsible for exposing Norfolk Shipbuilding and Drydock Corporation workers to asbestos through work on their steam products. People who worked with these products were wrongfully exposed to asbestos.

Crane Company is another viable company that made asbestos-containing products used in shipbuilding at the shipyard. These products included mechanical gaskets and valves which would have been used by tradesmen, including pipefitters.

Several victims have filed successful asbestos lawsuits against these asbestos companies.

04. Filing Asbestos Claims

Asbestos Company Trusts

Wrongful asbestos exposure and the resulting lawsuits have contributed to more than 100 companies filing for bankruptcy in the last 20 years. As part of the bankruptcy process, many asbestos companies created trust funds. Asbestos trust funds provide compensation for current and future victims of asbestos-related conditions.

As part of their job duties, many shipyard employees came into contact with asbestos. Shipyard workers who developed an asbestos-related disease are eligible to file an asbestos claim with the product manufacturer’s trust.

Asbestos Company Trust Funds and Eligible Years of Employment

The following companies provided asbestos products to Norfolk Shipbuilding and Drydock Corporation. After facing many asbestos lawsuits and exposing innocent people to asbestos, these companies filed for bankruptcy and created trusts to pay victims. If an individual worked at Norfolk Shipbuilding and Drydock Corporation and developed a disease such as mesothelioma, they may be able to file a claim against these companies’ trusts.

| Asbestos Trust Funds & Eligible Years of Employment | ||

|---|---|---|

| Asbestos Company Name | Eligibility Start Date | Eligibility End Date |

| Armstrong WI Trust | 1/1/1961 | 12/31/1982 |

| Combustion Engineering | 1/1/1942 | 12/31/1982 |

| C.E. Thurston | 1/1/1952 | 12/31/1981 |

| Fibreboard | 1/1/1950 | 12/31/1982 |

| Flintkote | 1/1/1979 | 12/31/1982 |

| Owens Corning | 1/1/1950 | 12/31/1982 |

| Pittsburgh Corning | 7/1/1962 | 12/31/1982 |